Case Studies

A German customer was designing an ice machine with capacity 250 kg ice flakes / 24 hrs using propane refrigerant.

Challenge

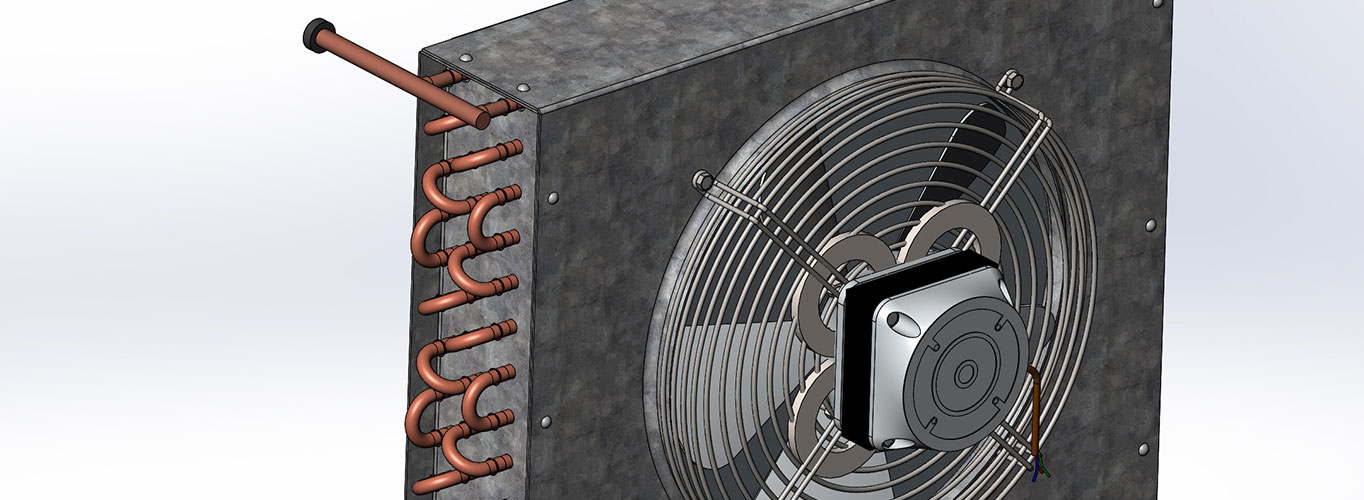

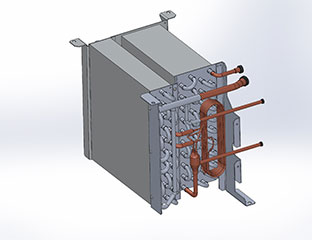

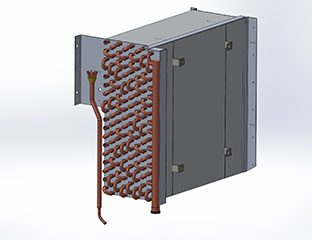

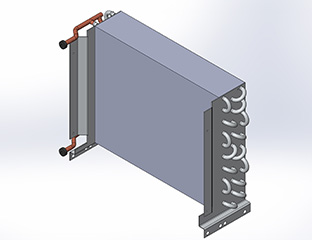

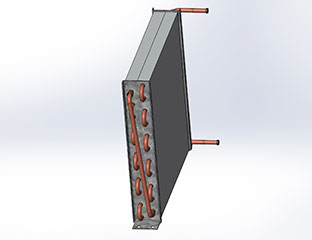

A complete condenser assembly ( condenser with fan, motor and shroud) was to be designed to produce the desired capacity in a specified cabinet size. The main challenge was the condenser internal volume to be very low, so as to allow a refrigerant charge of below 150 grams of propane.

Solution

Danvita’s design engineers used its wide range of Fin patterns and geometries with smaller tube diameters to arrive at a solution which provided a condenser with fan motor and shroud matching the given space envelope and capacity.

Conclusion

Danvita’s condenser assembly was tested by the customer and it’s performance exceeded the given requirement. Further, its refrigerant charge was only 130 gms which was 13.5% below the allowable limit of 150 gms.